Sealing Solutions for the Food and Pharmaceutical Industry

Freudenberg Sealing Technologies is a leading provider of high-performance materials and advanced products. In researching, developing, and introducing innovative product and process solutions, we draw on 175 years of engineering and materials expertise. Throughout, the technological desires and requirements of our customers have always been and continue to be at the forefront. The portfolio includes seals and plastic molded parts such as O-rings, rubber molded parts, rubber-metal composites, foam molded parts, semi-finished products, and machines for precision seal machining.

Food and pharmaceutical industry

Food and pharmaceutical products are key factors that contribute to human well-being and health. The manufacturing processes require a variety of solutions for materials and components and must meet national as well as international standards.

Key components

For the production of food and beverages – similar to the pharmaceutical industry – seals and plastic components, such as guides and sliding bushings are a key component. Over four decades of sealing experience in the food and pharmaceutical industries distinguishes Freudenberg Sealing Technologies as a developer and manufacturer of sealing and guide solutions. Old seals that no longer meet the current standards can, for example, be replaced by machined seals with the appropriate material pairing – suitable for the appropriate media. Reliable and durable compounds have already been developed for very abrasive and chemically aggressive media, for example.

Sealing and guiding solutions

- Hydraulic-pneumatic seals (piston/rod seals)

- Static seals

- Rotary seals

- Gaskets

- High pressure seals

- Large seals

- Miniature seals

- Special seals

- Guiding systems

- Backup rings

- Wipers

Materials

- Elastic and semi-elastic materials:

- TPU (AU/EU), HPU: premium, diet

- EPM, EPDM: diet, detec, spring

- NBR, HNBR: diet, detec

- FPM: diet, detec

- MVQ: diet, detec

- SBR & FFKM

- Hard plastics:

PTFE: natural, GF, Econol, Peek, Mica, POM, PA, PE, PP, PMMA, PET, PC, PSU, PPSU, PPS, PVDF - Alternative plastics:

Flat gasket materials in various designs

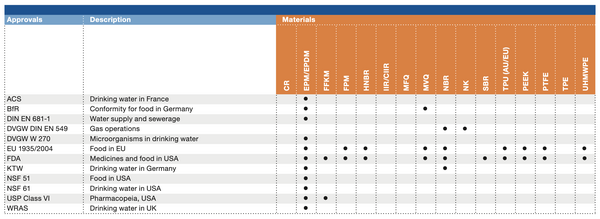

Approved Standards

- QS-Certificates:

ISO 9001, ISO 14001 - Approvals:

FDA (21 CFR 177.1550 und 21 CFR 177.2600) EU 1935/2004, KTW, DVGW, BfR, 3-A® Sanitary Standards, ACS, USP (Class VI), NSF, WRAS

Applications

Meat processing, milk refinement, beverage filling, confectionery and bakery products, fruit and vegetable pressing, oil and fat processing, milling and starch and starch production, coffee and tea processing machines, spice and sauce bottling, sugar processing, etc.

Industries and their applications

Freudenberg Sealing Technologies offers sealing and guiding solutions for a wide range of production machinery. Successful customer projects with tailor-made solutions have made us a leading supplier. Our strength is extensive knowledge of your requirements and conditions. Ask us!

Food in general

- Canning

- Dosing and conveying systems

- Fittings and valve seals for conveyor systems Cooling units

- Pigging systems

- Steam ovens

- Fryers

Pharmaceutical products and cosmetics

- Filling and dosing machines

- Tablet presses

- Laboratory centrifuges

- Powder dosing systems

Beverage

- Filling plants from ethanol to honey

- Centrifuges

- Separators

- PET blow moulds

- Heat exchangers

- Beer filtration

Milk and dairy products

- Milk separators

- Milk homogenisers

- Acidified milk production

- Cheese presses

- Packaging machines

- Portioning and dosing machines

- Filling machines for quark, yoghurt, etc.

Meat and sausage products

- Meat conveyor systems

- Smoking chambers

- Overpressure pasteurisers and sterilisers

- Gut brakes

- Cutter seals

- Bellows for vibration separation

Correct selection of materials

When selecting the material, several important selection criteria must be considered, such as the expected operating conditions, design requirements, approvals, standards and costs etc.

Operating temperature

- In which temperature range should the seal be used?

- What is the minimum and maximum temperature?

- Are there short-term peaks or continuous levels in these temperature ranges?

Chemical resistance

- Against which media must the seal function and be resistant?

- Are there any interactions, e.g. acids and alkalis?

- What are the temperatures of the media to be sealed?

- Are oils or greases used during assembly?

Mechanical properties

- How is the seal inserted? Is it a static seal, dynamic seal, or a non-static, dynamic seal?

- For dynamic seals: How high is the mechanical stress?

- Is the seal rarely, regularly or permanently moved?

Engineering requirements

- Component geometry with description

- Critical dimensions and tolerances

- Details of the desired service life

- Installation and assembly considerations

Seals and sealing materials

Thanks to many years of experience, Freudenberg Sealing Technologies can offer complete solutions:

- Standard O-rings, machined O-rings, FEP/PFA coated O-rings

- Standard seals made of suitable and approved materials

- Customised solutions

Your advantages

- Longer service life

- Lower maintenance and life cycle costs

Sealing materials and plastics

In our brochures you will find a wide range of matching materials and on our website you will find an overview of elastomers and the Media Resistance Guide to help you choose the right material. With this tool you have the possibility to check several media at the same time.

Approvals/Certifications

The materials for O-rings and sealing profiles manufactu- red from them must meet high legal requirements.

Special material mixtures have also been developed for this purpose. Ask us!

Customer service and packaging

Customer service, comprehensive advice and technical support are our top priorities. From development through the production process to the desired packaging, we rely on trusting cooperation with our customers.

- On request, application-specific material mixtures, types of metal and refinements (e.g. surface treatment) are available

- An extensive range of standard articles are available on stock

- Technical advice for individual problem solving and moulded part design

- Construction and material-appropriate design of the component

- Prototype production and product optimisation

On-site training — a helpful option

We offer training for your staff on the correct handling and use of seals as well as on assembly and storage.

We …

- are a sealing and plastic parts manufacturer

- see ourselves as a partner to our customers

- are independent, holistic and solution-oriented

- are an international network company and we work world-wide

- see our company culture like life: varied, complex and exciting

- value greatly the individuality and the expertise of the staff

- are committed to high professional ethics and integrity in all we do

All this creates a passionate, innovative and dynamic team to support your business.

Want to learn more?

Visit our Freudenberg Sealing Technologies website